CREAVITY

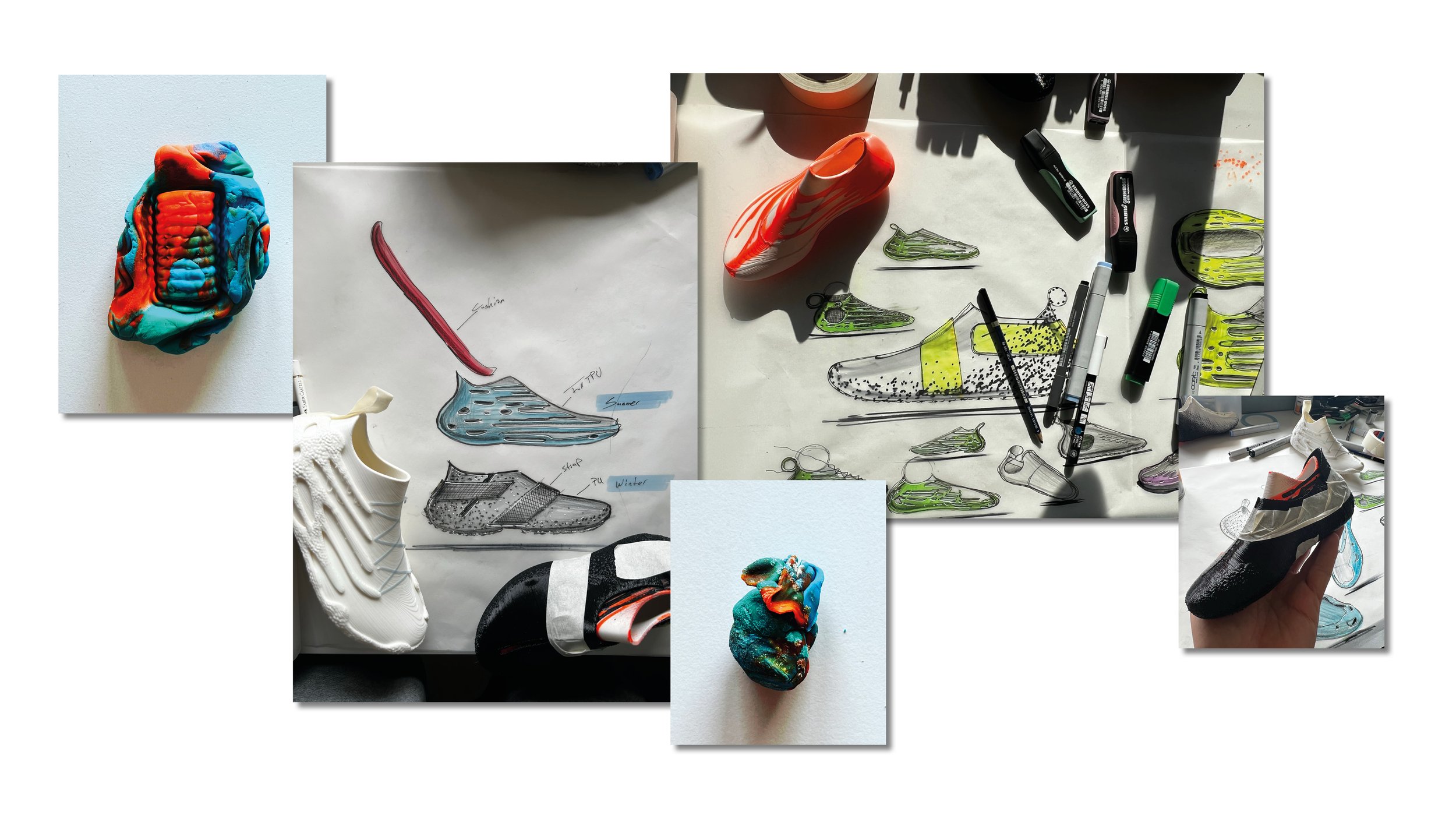

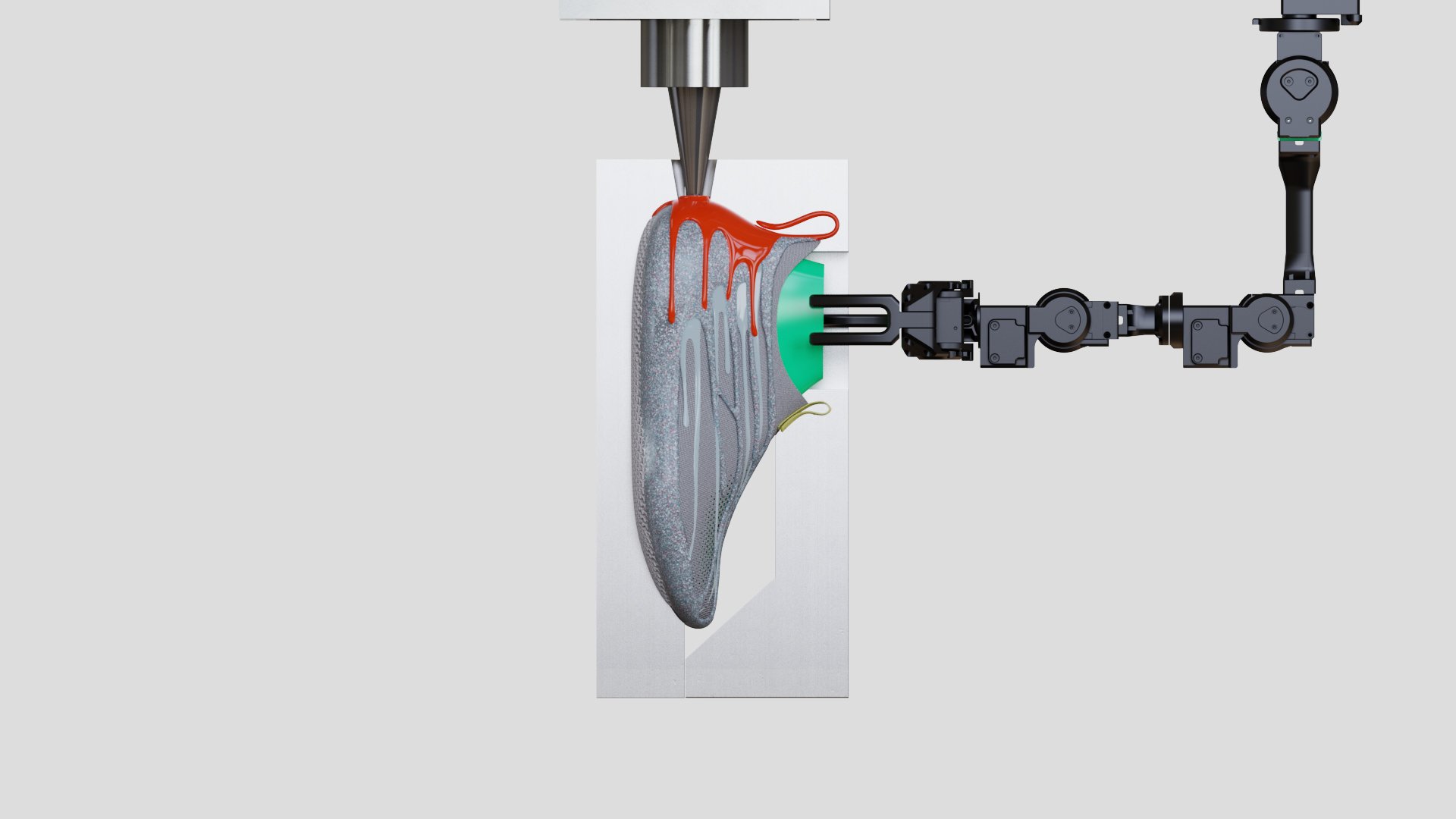

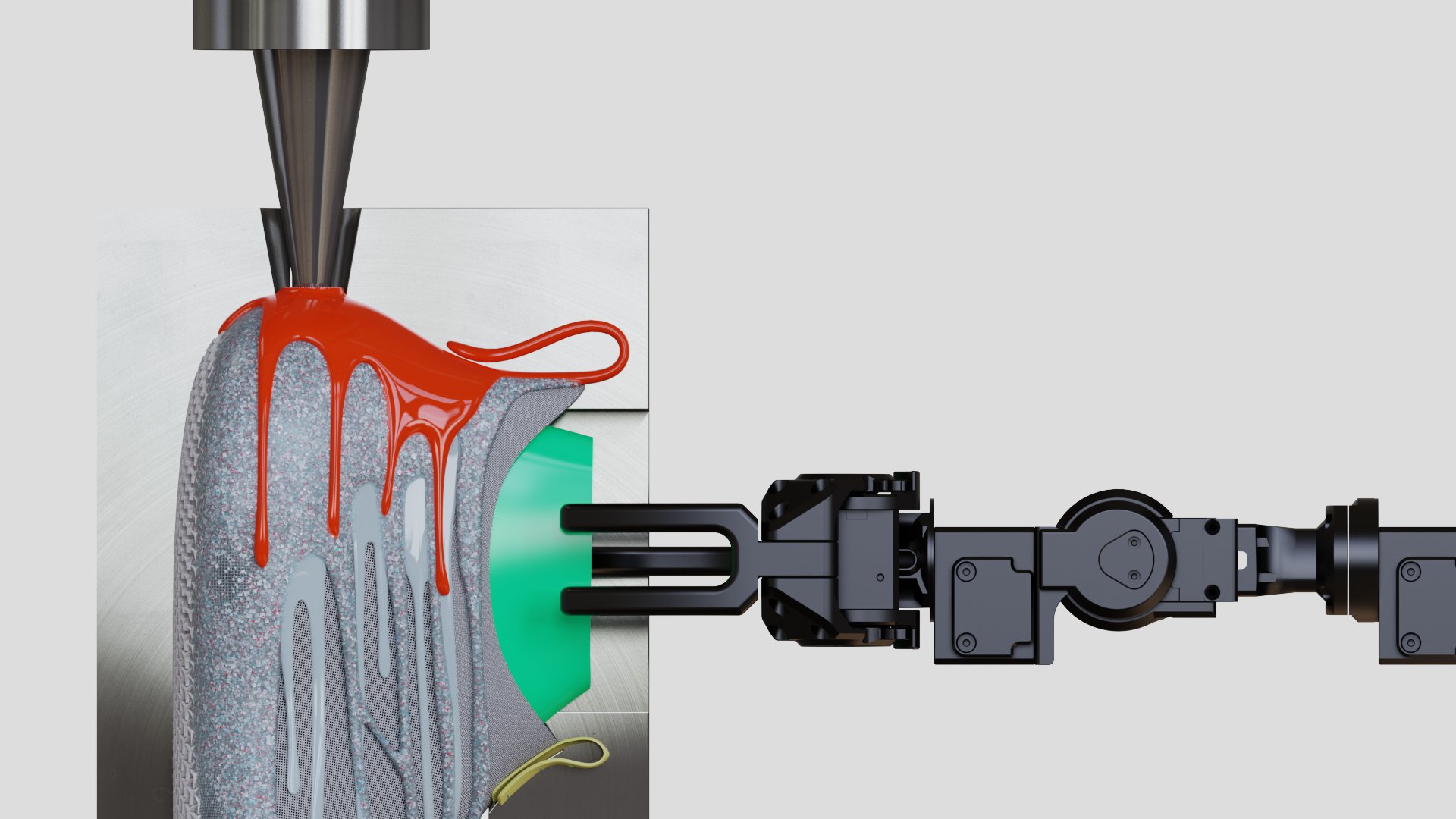

In this personal project I participated in the instagram #lacelesschallenge in 2022. I call it Creavity (Creativity meets Gravity). This years challenge is a collaboration with @lacelessdesign @desma_schuhmaschinen and @footwearology_lab . Desma is well known for the overinjection prodution method, where PU or TPU is overinjected on a knitted sock, The interesting thing is that they can produce very quickly, mainly automated and locally. So monomaterials are possible, which make it sustainable as well because you can put the shoe into the recycling process very easily. During my creative phase I painted a 3d print (see process images) on the heal. The color dripped over the last and found its way by gravity. This was the initial idea for Creavity. Why dont we use the overinjection in a more artistic, natural and flowing way? By learning some Footwearology tutorials I was also able to learn some fundamentals for knitting and sneaker production. This helped so much during the next phases.

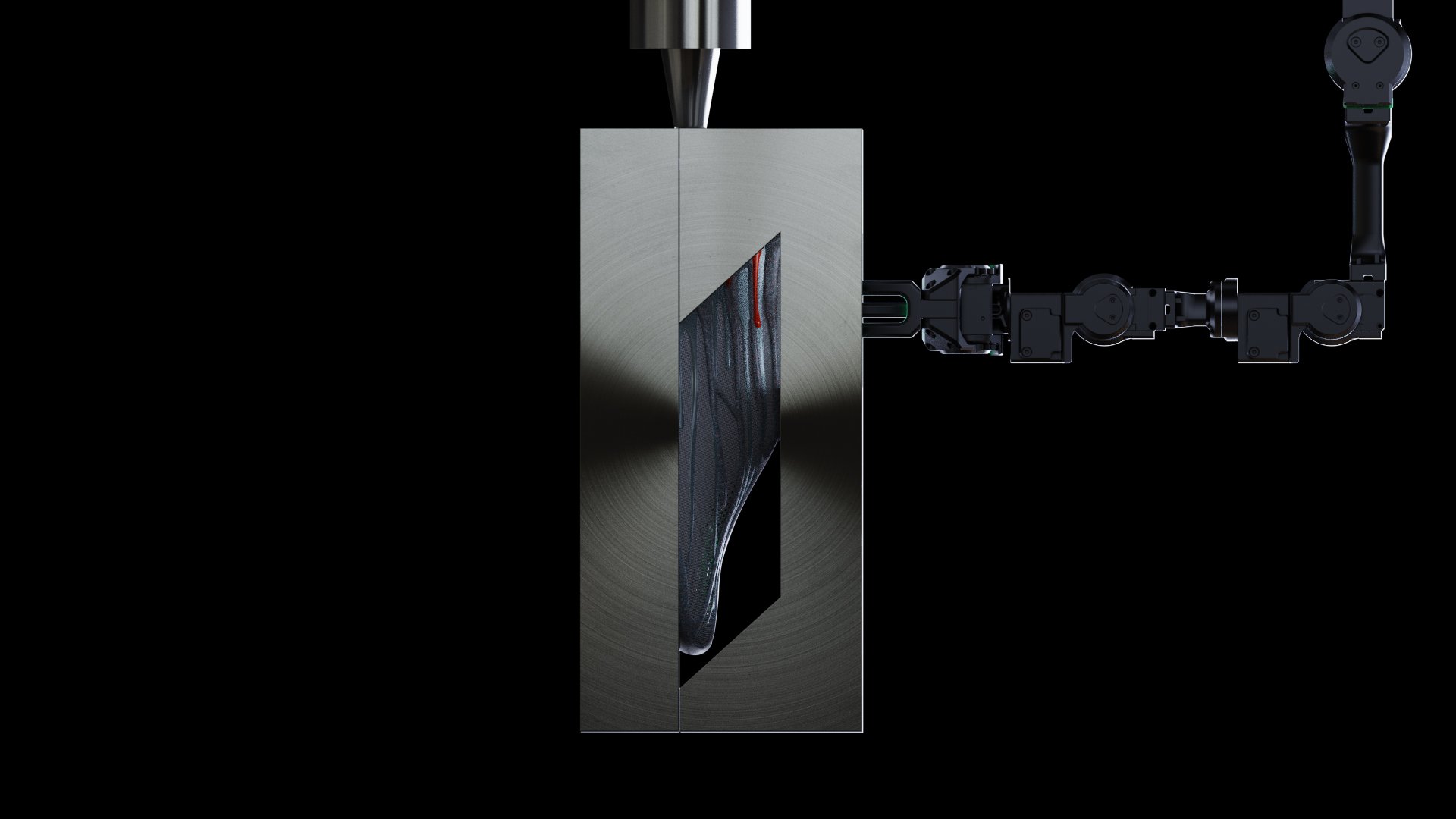

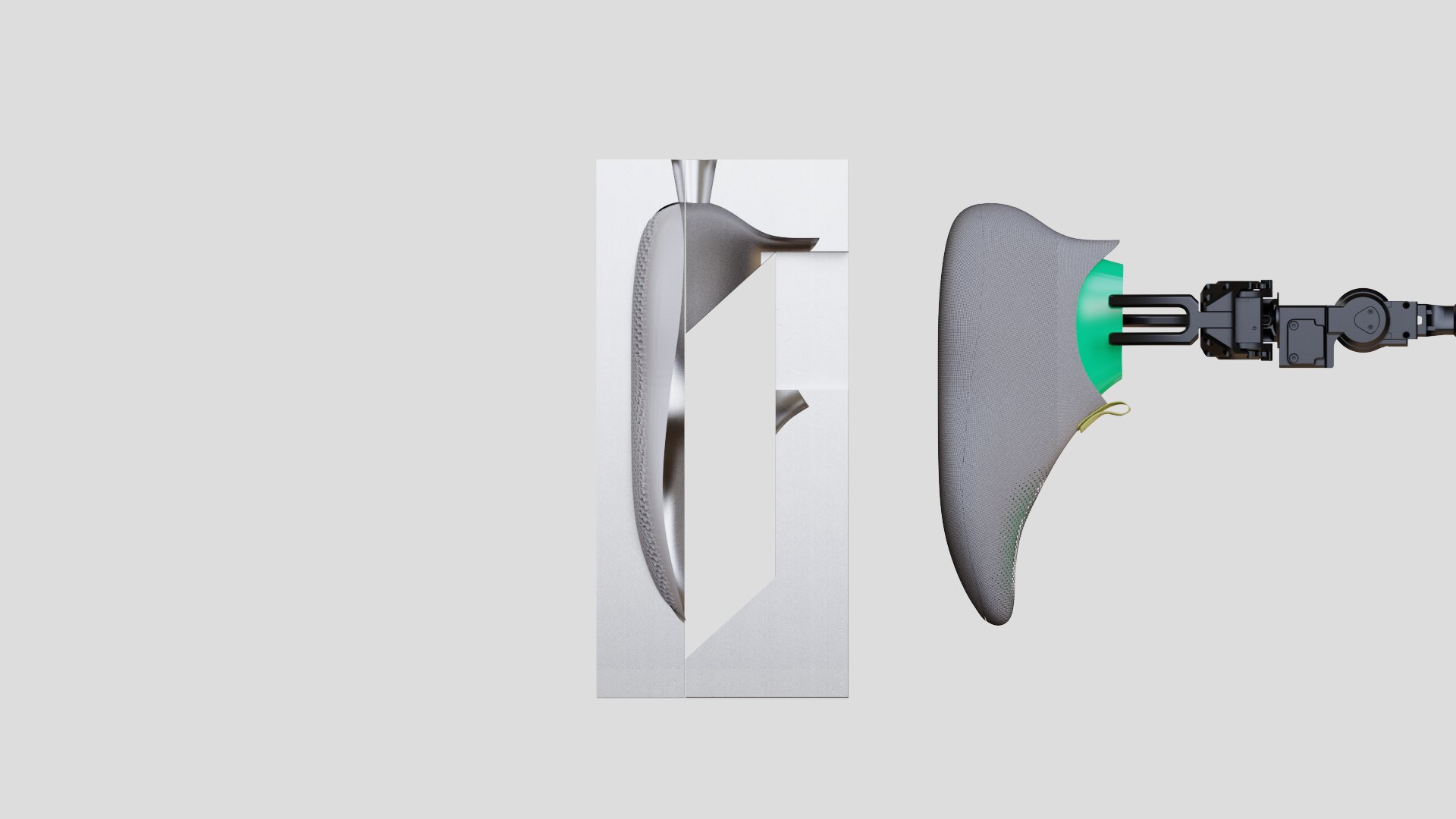

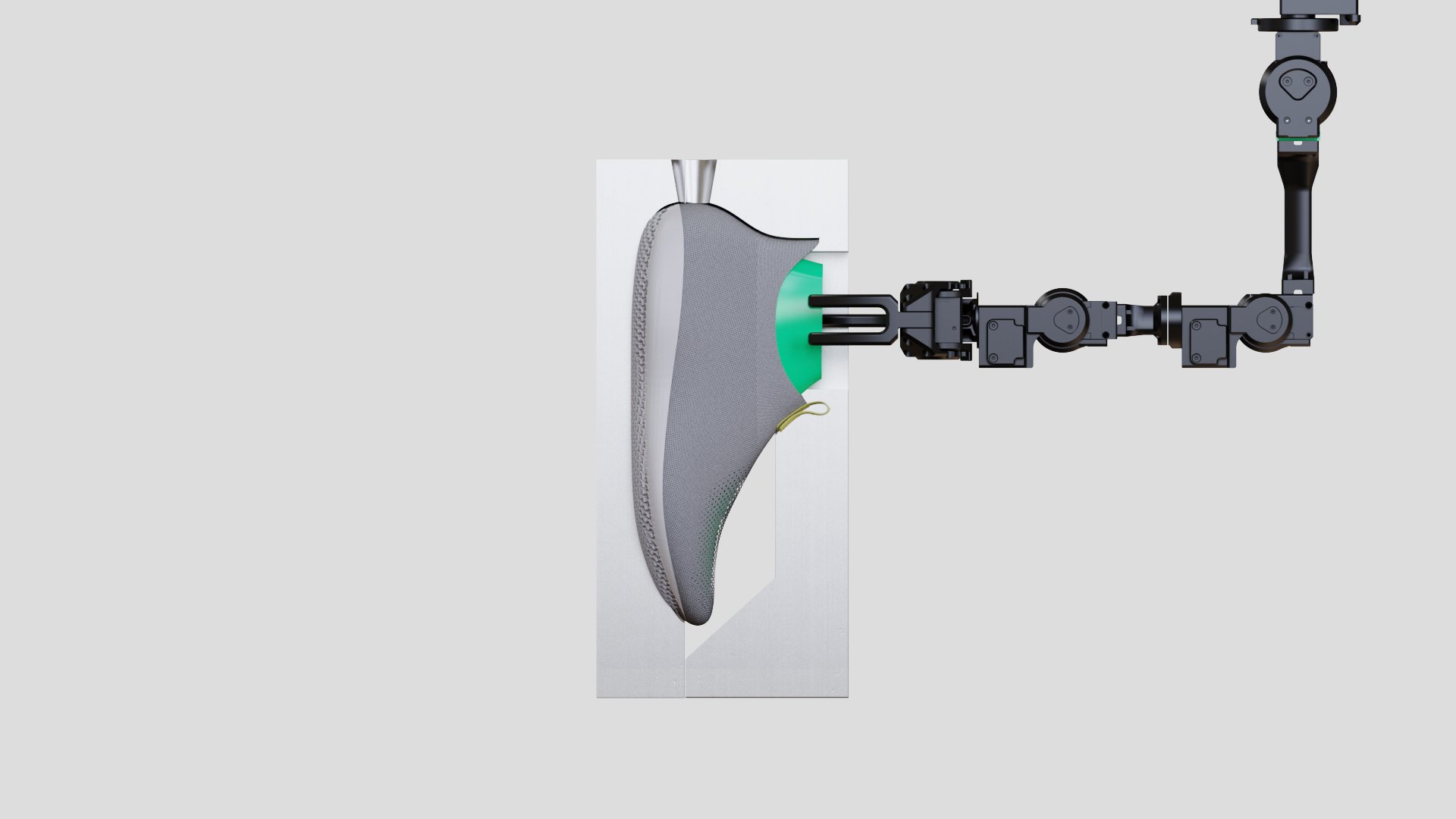

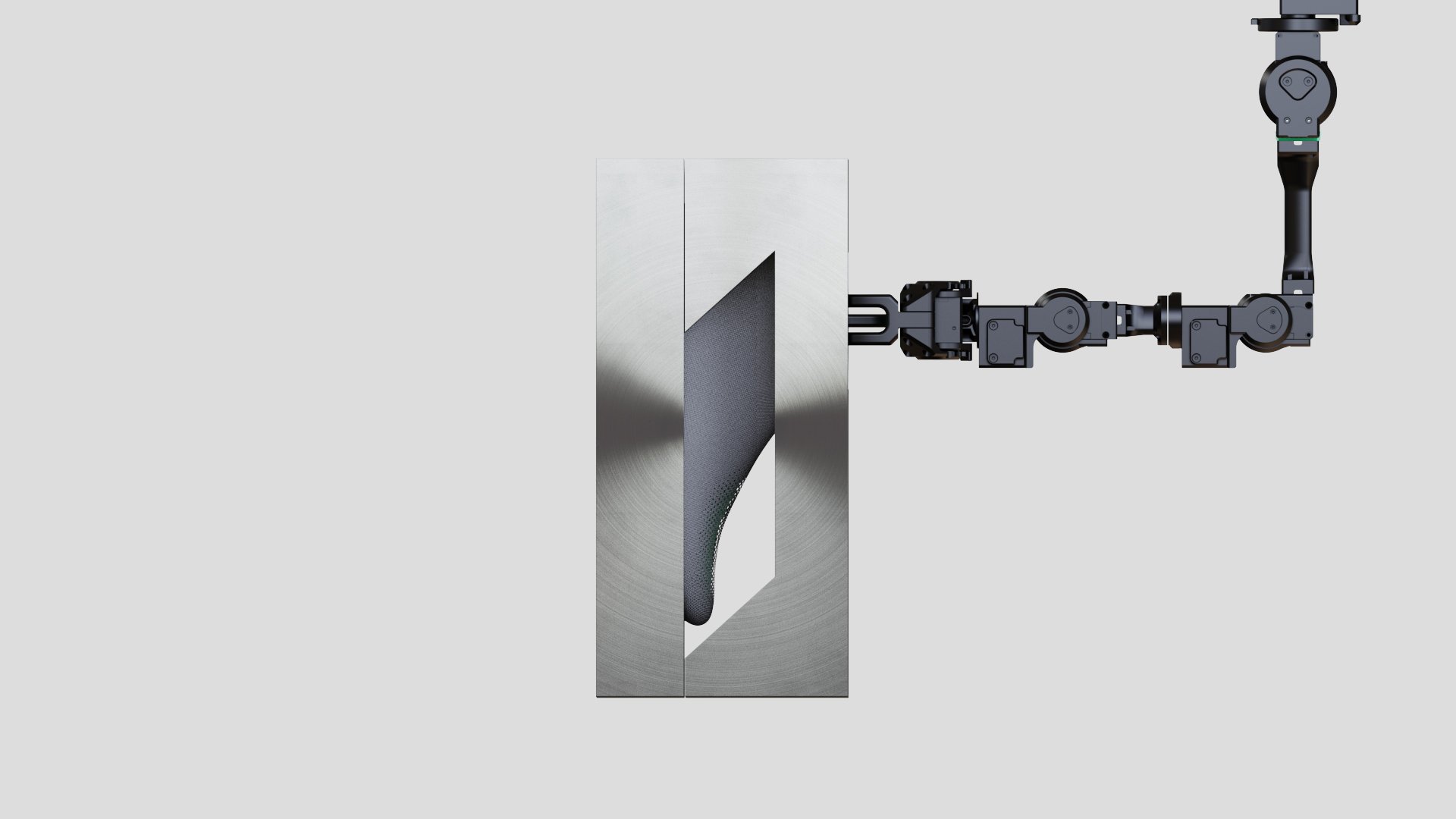

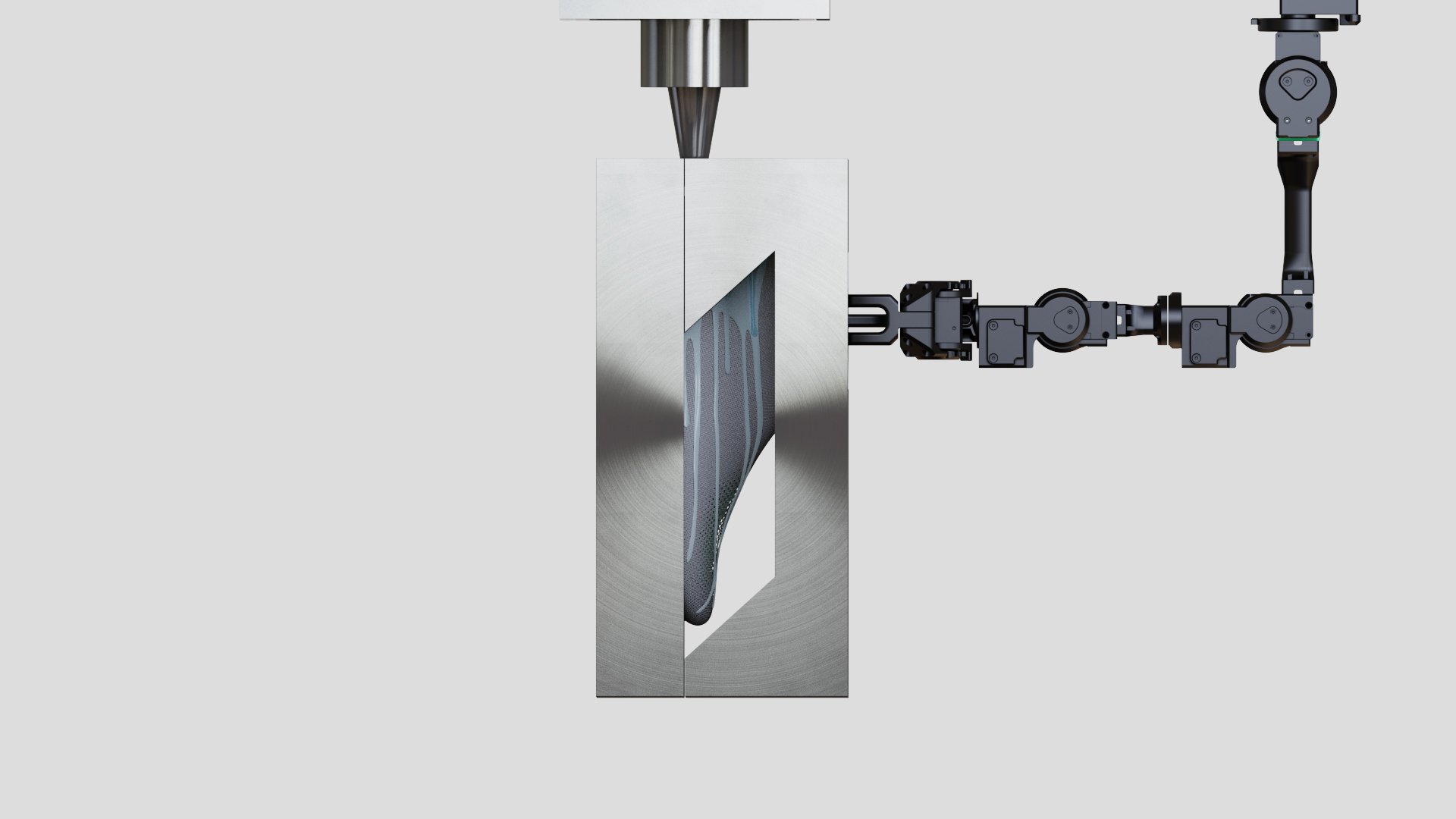

TOOLING CONCEPT

Here you will see how it could be made. I would call this production method 50% freesytle and 50% guided molding. The idea is that the lower part is comparable to a normal injection process and the upper part is open, so the plastic can flow on top of the upper, so every sneaker will be unique and a piece of art. On picture nr. 2 you see that the premolded outsole is positioned in the lower tooling. Then the knitted sock will be put on top of it. The different TPUs flow around the 2 parts and connects everything together.

CMF

Some in- and exterior shots and different CMF options which highlight the concept.